Traveling Water Screen

(Also known as Rotating Water Screen, Rolling Water Screen, Mechanical Water Screen)

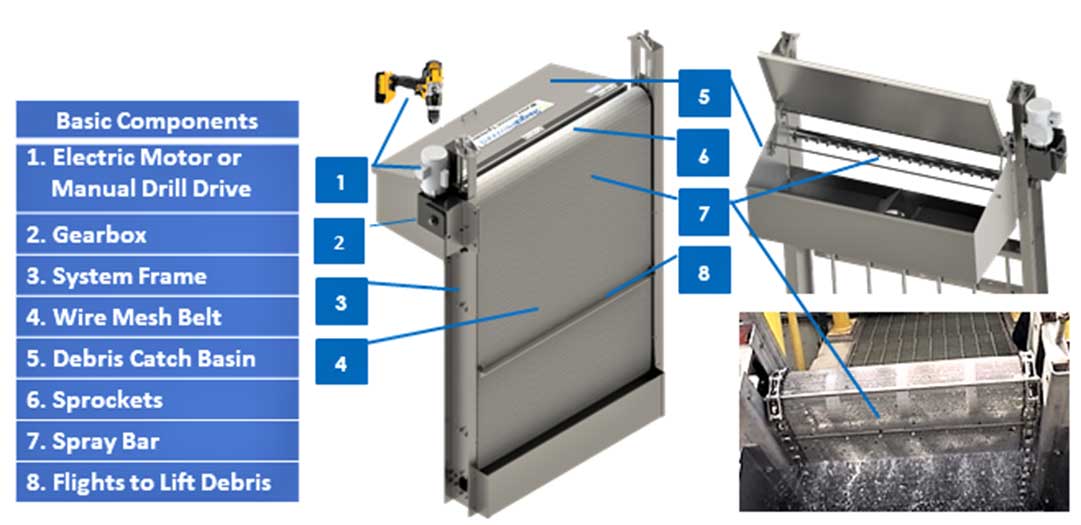

A Traveling Water Screen is a self-cleaning water filtration system with a mechanically or manually rotated wire mesh belt. The belt lifts debris from the water source and an internal spray-off system deposits it into a collection trough or on to a conveyor for disposal.

Cambridge Water Screen Systems is part of the Regal Rexnord cooling tower product portfolio such as Addax® Couplings & Fan Brakes, Falk® CTA Series Gear Drives and Marathon® Globetrotter® Motors.

Cambridge Water Screen Systems is a trusted leader in custom, PE certified design and (US) manufacturing of both new and replacement, high efficiency thru flow Traveling Water Screen systems:

- Traveling Water Screens for cooling tower basins. (Traveling Water Screens vs. Traditional Stationary Water Screens).

- Traveling Water Screens for manmade and natural water applications such as rivers, lakes, etc.

- Traveling Water Screens for a pump house.

- Traveling Water Screens to remove storm water debris

- Traveling Water Screens for irrigation

See videos of Traveling Water Screens on our YouTube channel.

Debris Hopper with raised drain (clean)

Debris Hopper with raised drain (with debris)

“Flights” on Belt to Lift Larger Debris from the Water

Traveling Water Screen for Cooling Towers

We design and manufacture Traveling Water Screens for both new cooling tower construction and replacement systems.

Advantages of a Traveling Water Screen compared to traditional stationary water screens:

- Self-Cleaning: Reduces maintenance costs

- Increased Safety: No more lifting water screens to clean

- Highly Efficient: Removes harmful debris from the water

- Easy Drop in and Replacement: No modification of the basin required

Manual Traveling Water Screens in a Cooling Tower

Motorized Traveling Water Screens in a Cooling Tower

Replace Old Water Screens with Traveling Water Screens: We offer Traveling Water Screen systems to replace old, damaged, or inefficient water screens without the need to modify the structure of the basin. It is truly a drop in and replace.

Old Cooling Towers with Traditional “Lift Out & Clean” Water Screens: In many cases, aging (normally wood) cooling towers need to stay operational for as long as possible. The problem with older cooling towers is that larger fragments of wood and plastic will fall into the basin from the tower itself. Combine this debris with pieces of trash and natural debris from the surrounding environment and it can mean serious trouble for heat exchangers and other downstream systems.

When the debris builds up on the traditional water screens, a crew of people are required to lift the screens out of the water to be cleaned. As the water screens are lifted out of the water, gravity takes over and much of the debris will fall off the screens and back into the water where it finds its way downstream to the heat exchangers and condensers.

As debris builds up and obstructs the flow rate of cooling water through the heat exchangers, the efficiency of the cooling system is degraded.

Heat exchanger tubes obstructed with cooling tower debris

A Painless Process Because of a Narrow Installation Footprint: Some people mistakenly believe traveling water screens are not appropriate in a cooling tower application. This is because the only traveling water screens they have seen are the bulky type systems you would see on a lake or river at a power plant.

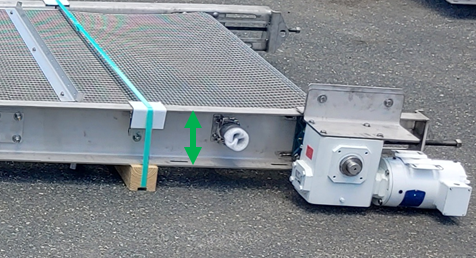

Cambridge Traveling Water Screens have a narrow installation footprint due to being a “conveyor belt-style” type of system (see picture on the right – green arrow). This is what allows us to replace the old water screens without having to modify the structure of the cooling tower basin.

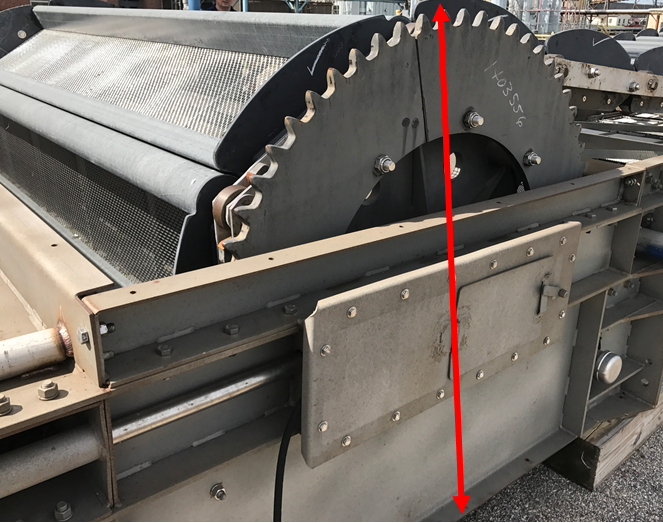

In contrast, a “basket-style” type system (see picture on the left) has a series of mesh baskets which are connected by chains that travel around a large sprocket. This gives the system a very wide installation footprint (red arrow) which makes them impractical for a cooling tower application.

Basket-Style Traveling Water Screen

Cambridge Belt-Style Traveling Water Screen

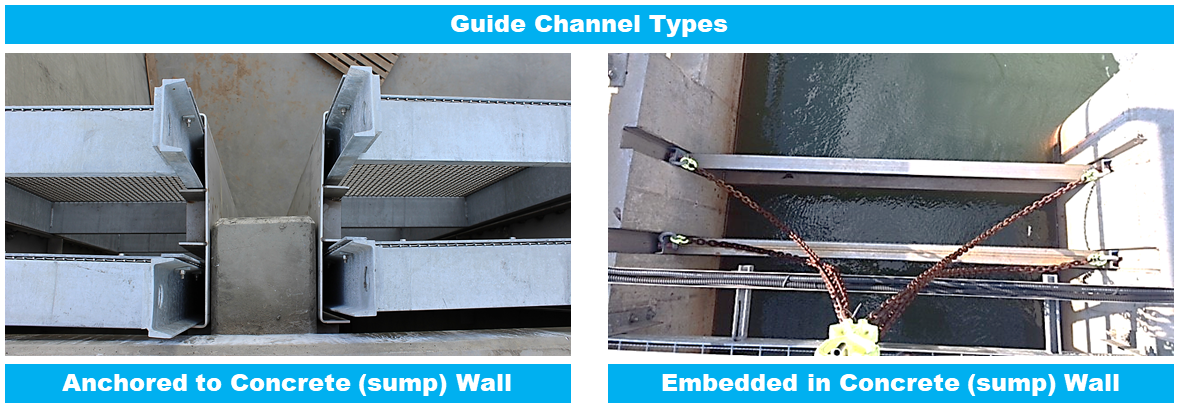

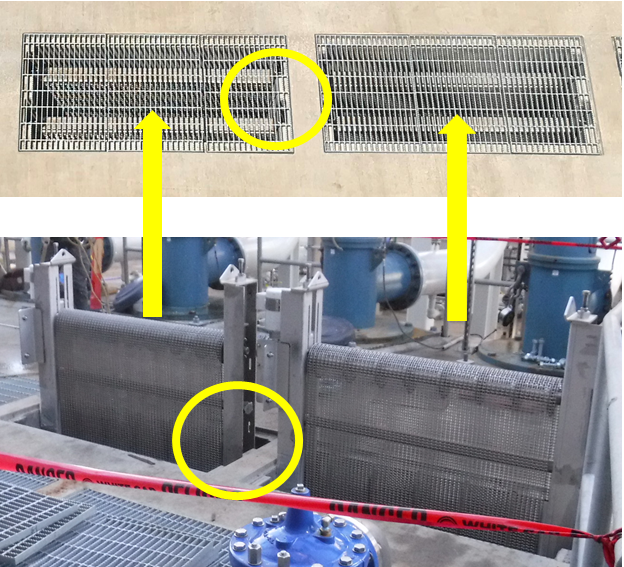

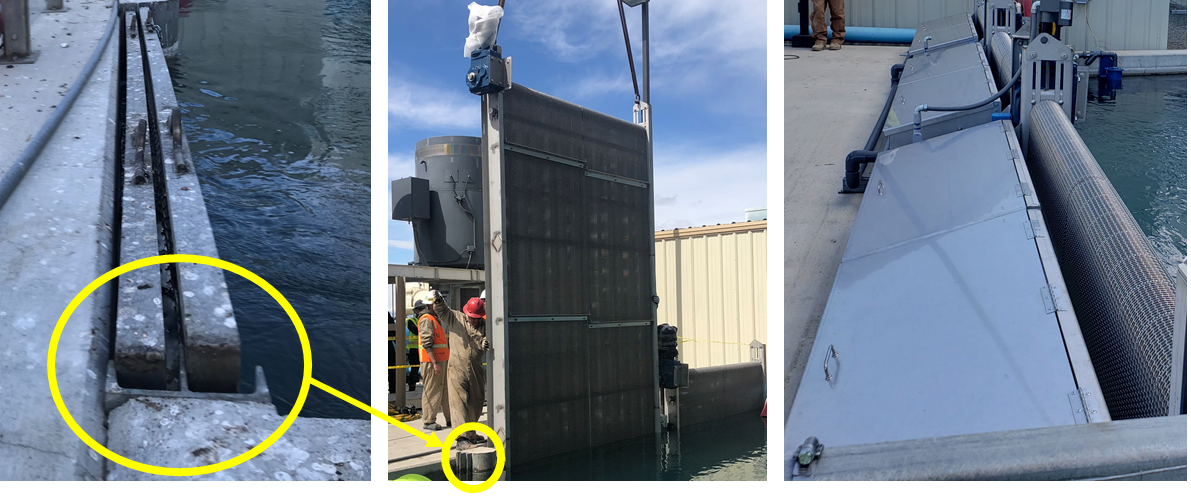

Two examples of replacing traditional stationary water screens in a cooling tower basin with new traveling water screens. We are able to use the existing guide channels and install the Traveling Water Screens without modifying the original structure of the basin.

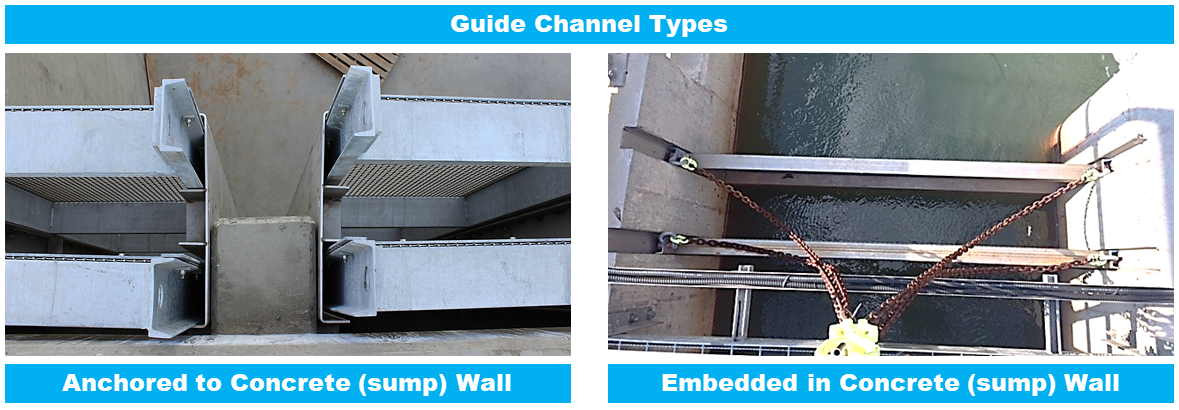

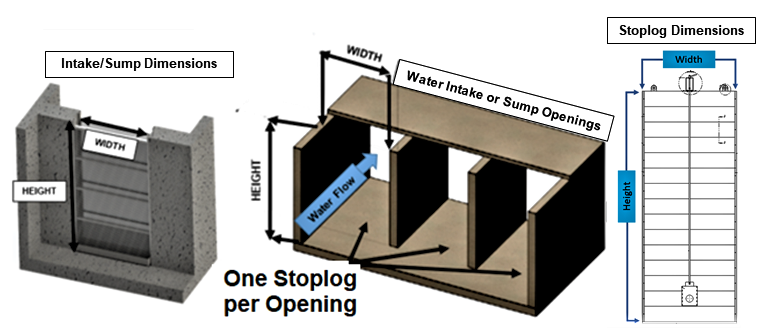

Traveling Water Screen Replacement Example 1: Stationary water screens (5’ wide x 18’ tall) with guide channels embedded in the concrete.

Traveling Water Screen Replacement Example 2: Stationary water screens (10’ wide x 20’ tall) with guide channels anchored to the concrete. If the old guide channels are corroded or unserviceable, we will fabricate new guide channels.

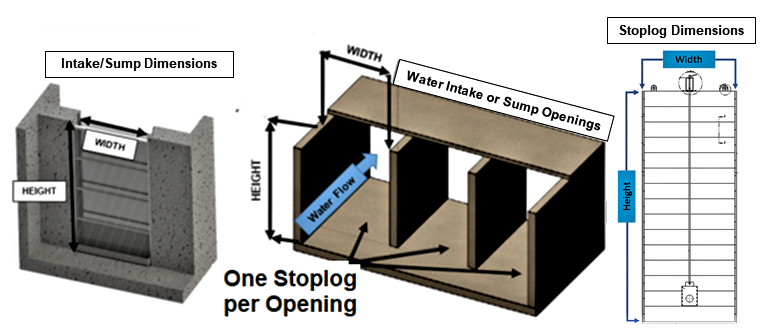

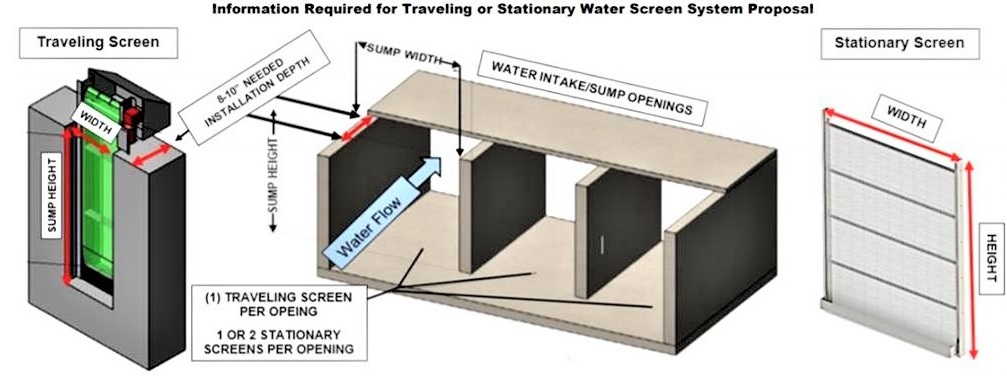

If you would like a Traveling Water Screen system proposal, please click on this link or the Request Proposal Tab. Please fill out the form as completely and as accurately as possible. If available, please provide construction drawings and/or photographs of the water intake structure and the existing water screens. In addition, provide information on any special requirements/conditions for the project.

Traveling Water Screen on Natural Waterway (30’ tall x 12’ wide)

70-foot-tall Traveling Water Screen Installed to Filter Cooling Water from the Ohio River

Ready to get started?

Get in touch with Us!