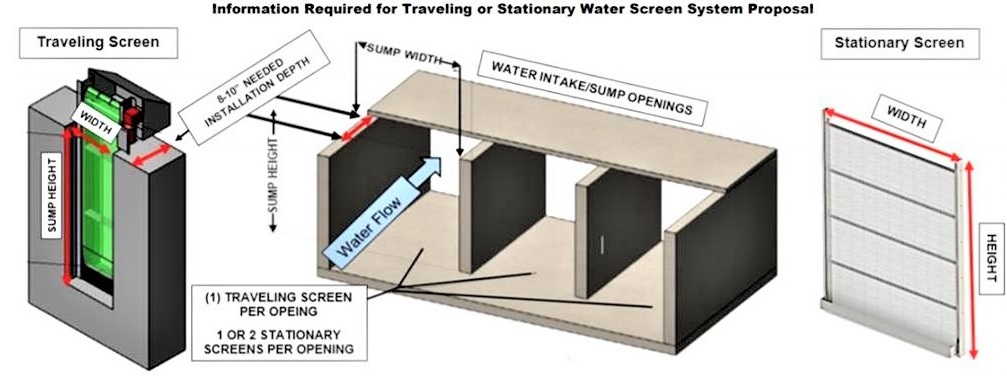

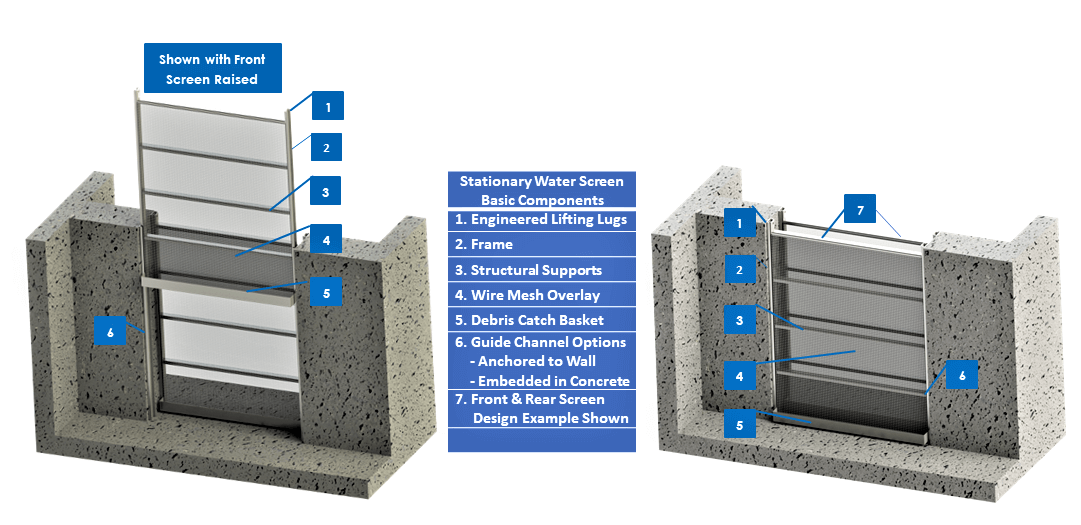

A Stationary Water Screen is an engineered system with a frame, structural supports and a woven mesh overlay. Stationary Water Screens are used to filter debris from a manmade (i.e. cooling tower basin, pump house) or natural water sources (river, lake etc.) As the screens becomes obstructed with debris, they are lifted out of the water and the debris is manually washed off.

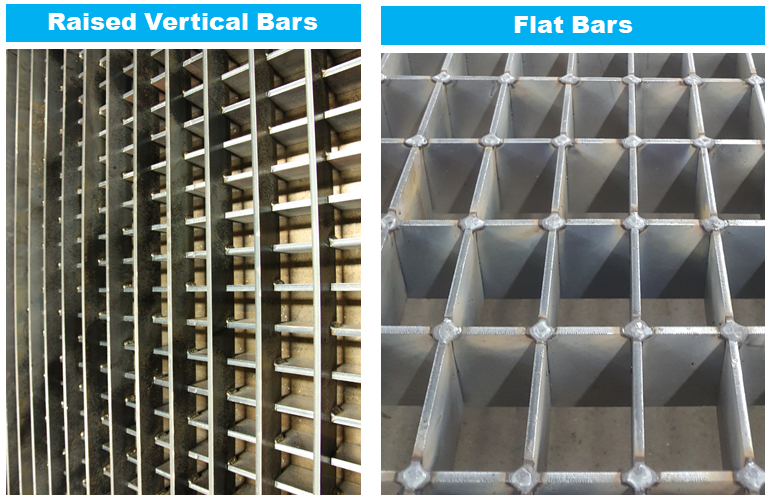

Cambridge Stationary Water Screens are configured per customer specifications or custom engineered solutions:

- There are no size limitations

- System designs receive Professional Engineer (PE) certification “stamp”

- Available in galvanized, T304 and T316 and with optional mesh opening sizes

Example Stationary Water Screens in Cooling Tower Basin 12 feet wide x 25 feet tall

See below for examples of custom Stationary Water Screen systems:

- Installed when large Traveling Water Screens are pulled out of the water for maintenance

- Municipal water intake on a river with opening at multiple depths

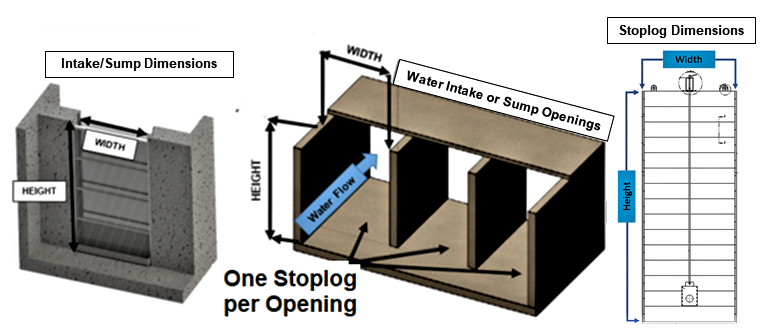

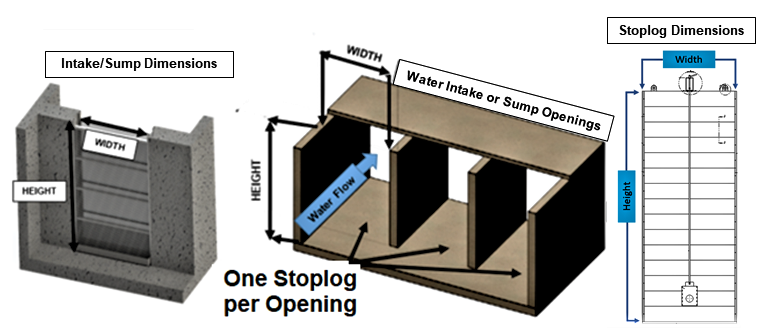

Cambridge Stationary Water Screen systems are typically designed as a two screens system with a front and rear screen installed in each water intake. They are designed with engineered lifting points and a debris basket at the bottom of the screen to catch debris as it is lifted out of the water for cleaning.

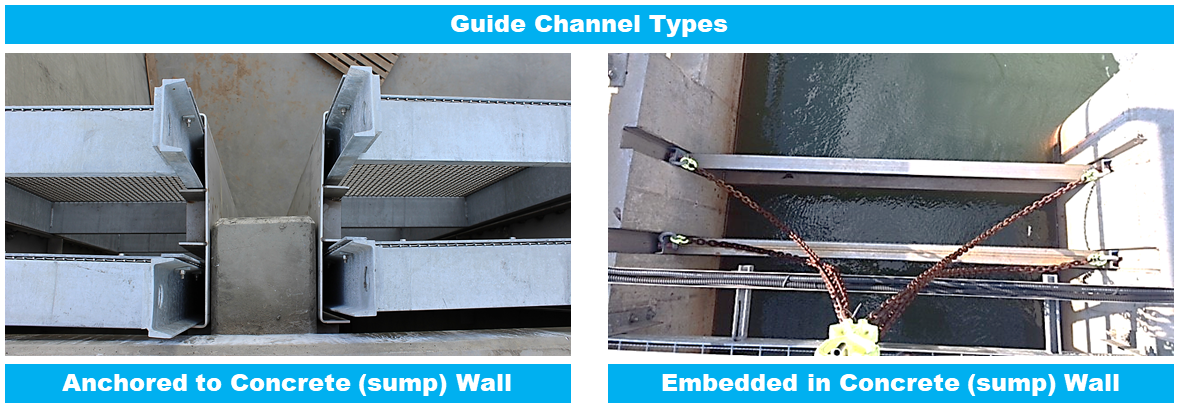

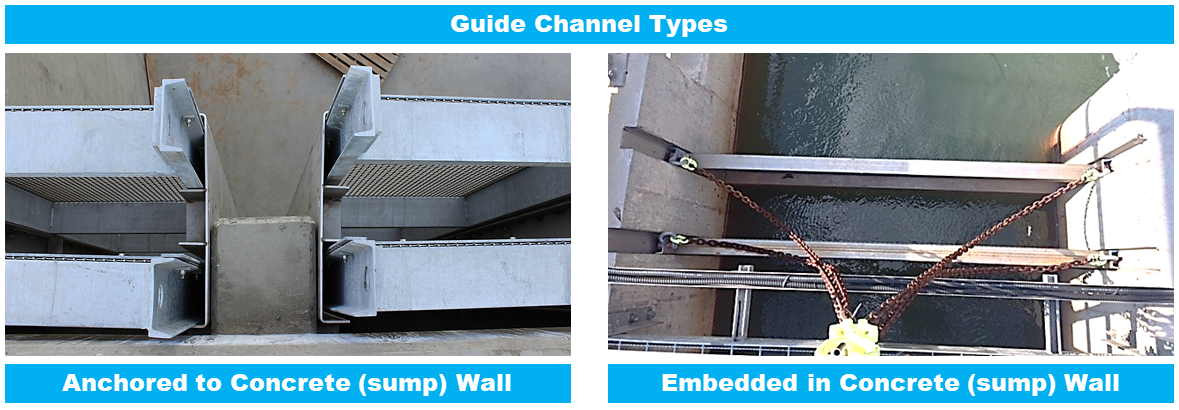

Fabricated guide channels are available as either bolted to the water intake structure or embedded in the concrete (embedded guides shown in picture).

Example of fabricated guide channels bolted to the water intake (sump) wall.

Also shows the engineered lifting lugs Top view of fabricated guide channels and lifting lugs.

Example of water intake (sump) openings prior to installing Stationary Water Screens.

Example of the same water intake with Stationary Water Screens (20 feet tall) installed with fabricated guide channels that are anchored to the concreate (see below for a view from the top)

Example Stationary Water Screens with fabricated guide channels bolted to the water intake (sump) wall. Also shows the engineered lifting lugs.

Example of Custom Stationary Water Screen system for municipal water intake on a river

with multiple opening at varying depths and guide channels to lift to the surface for cleaning.

Custom Stationary Screens for Large Traveling Screen Maintenance

Large Traveling Water Screens that are installed on natural water sources (i.e. river, lake, bay etc.) need to be pulled out of the water for maintenance from time to time. In order to accomplish this without an outage (and while maintaining debris management), Cambridge Water Screen Systems designs and fabricates custom stationary water screen systems that are installed in front of the Traveling Water Screen.

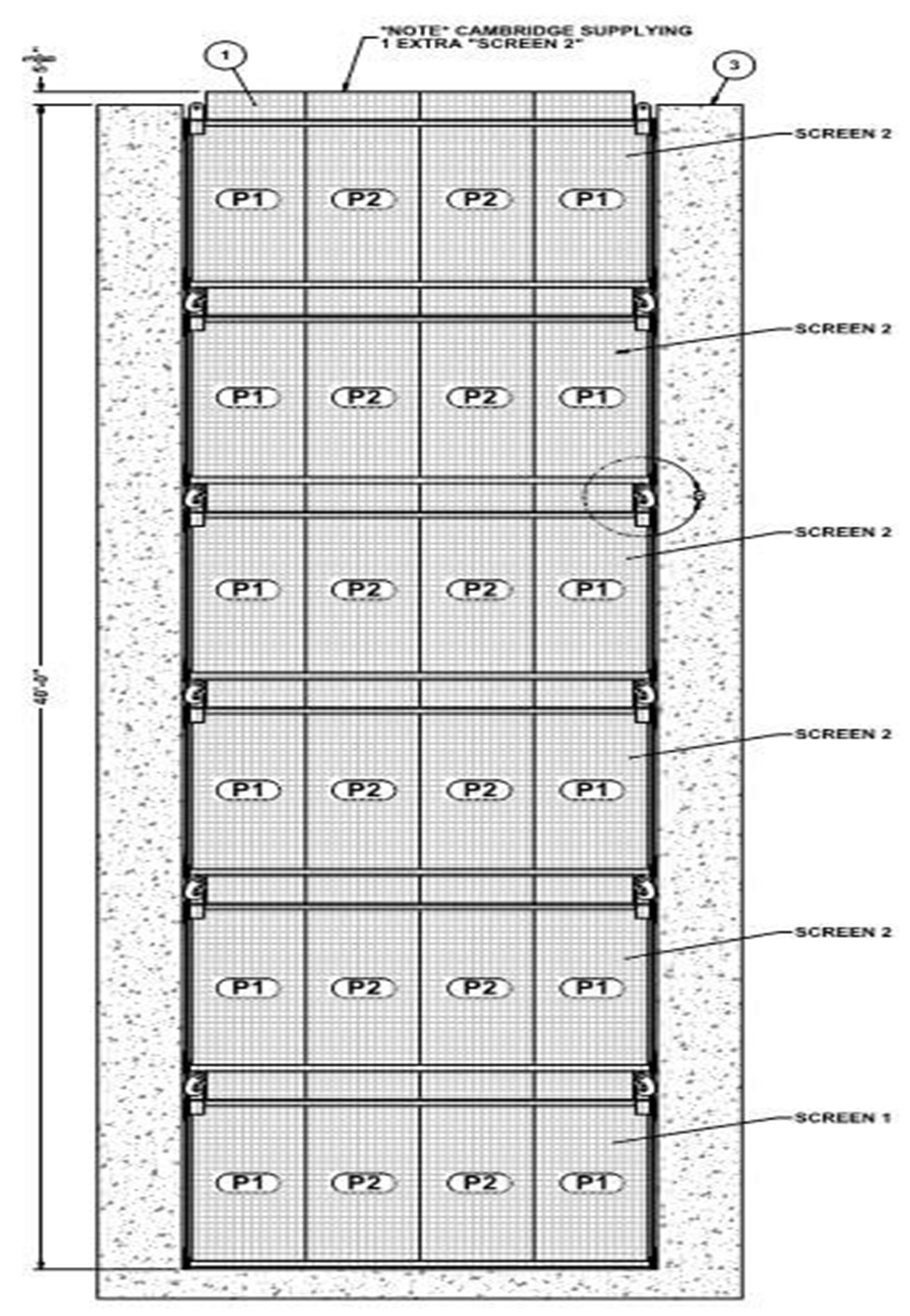

These systems can be designed as one complete unit or in multiple sections that are latched together. These custom systems are designed with significant framing and bracing to maintain structural integrity, and with a 3/8” mesh overlay to maintain debris management. Below are some project examples.

Example of custom Stationary Screen as one complete unit, with pressure relief door

Example of custom Stationary Screen for Traveling Water Screen Maintenance with 6 latching sections (12 feet wide x 40 feet tall)

(Also see photo below)

Example of Custom Stationary Screen for Traveling Water Screen Maintenance showing one of the latching sections. Note the Trash Rack like structure for strength with the wire mesh overlay for debris management.

Get in Touch With Us

If you’re looking for a custom-made stationary water screen, Cambridge Water Screen Systems has the solution. Call us at (443) 331-5520 and talk with one of our customer service reps today or fill out our contact form. We look forward to advising your business in your water-filtering journey.