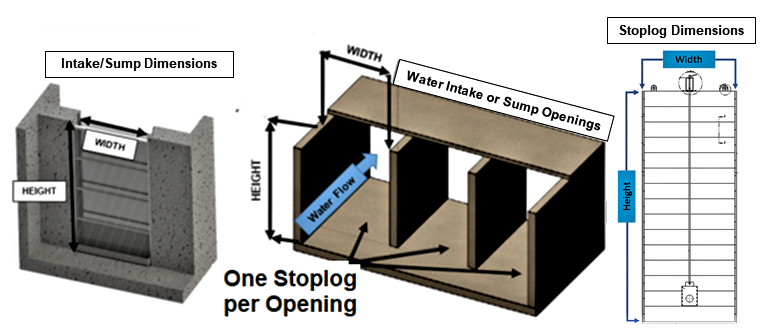

Stoplogs for Water Flow

Stoplogs are a critical component of water screens used by various industries, including power generation, water treatment, and industrial processing. Cambridge Water Screen Systems is the nationwide choice for stoplog installation, traveling water screens, stationary screens, and trash racks. We understand the critical role of these components in operation and maintenance of water screen systems, and we are committed to providing our customers with the best possible solution.

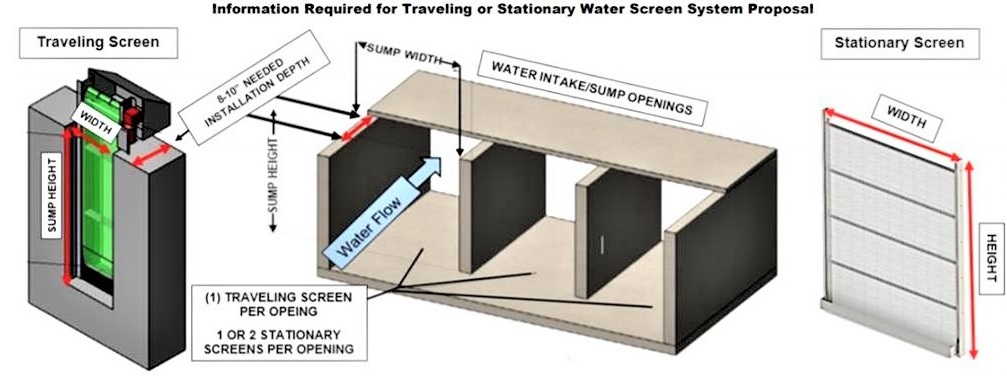

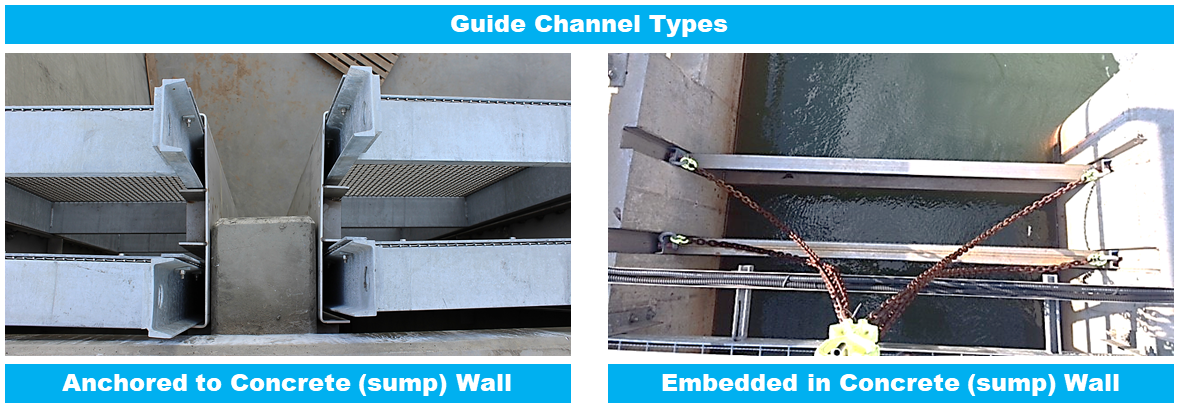

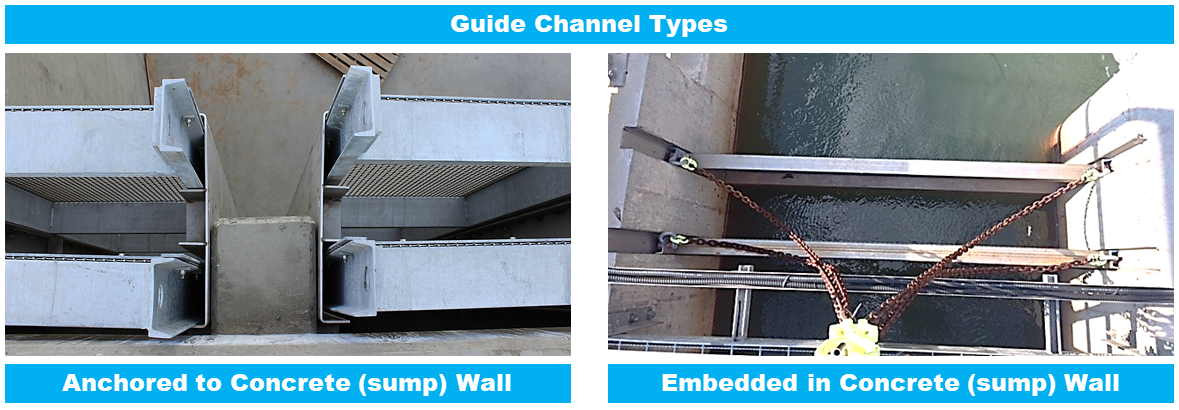

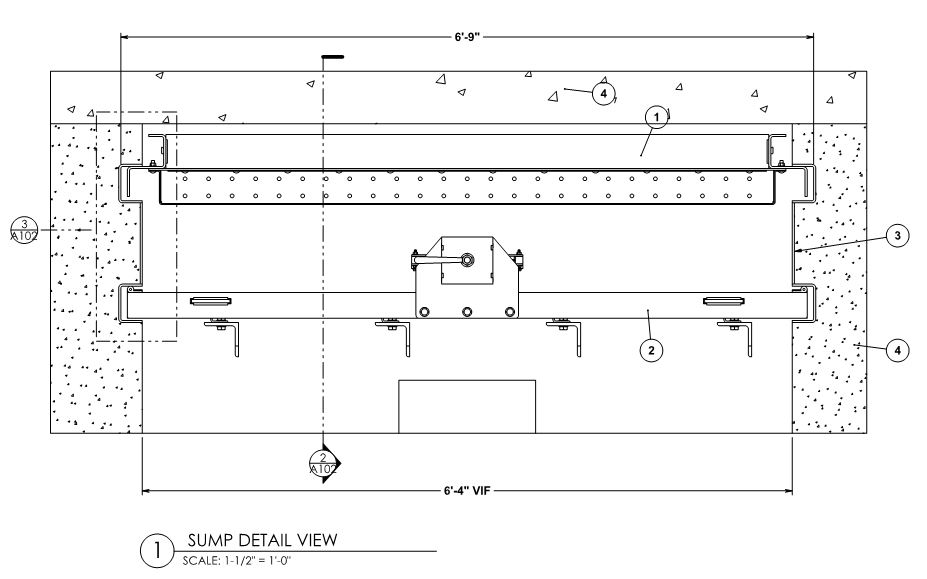

Example of a custom Stoplog and Stationary Water Screen in a cooling tower that were designed to fit existing guide channels embedded in the concrete (top down view shows Stoplog in the rear guide and the Stationary Water Screen with perforated debris basket in the front guide) Note: A custom frame was required for the Stationary Water Screen because the existing guides had not been properly engineered for the size of the required frame based on the open area and flow rate through the water screen.

What are Stoplogs?

Stoplogs are hydraulic elements that adjust water levels and discharges from rivers, lakes, canals, and other manufactured water sources. They are composed of beams or boards stacked on each other inside a gate or channel. The pressure these beams exert can increase or reduce the amount of water that flows through them and are great tools for temporary channel closures.

Depending on the application, they can be designed in multiple sections or as one complete unit. They are typically made out of high-pressure-resistant aluminum or stainless steel.

What are stoplogs used for?

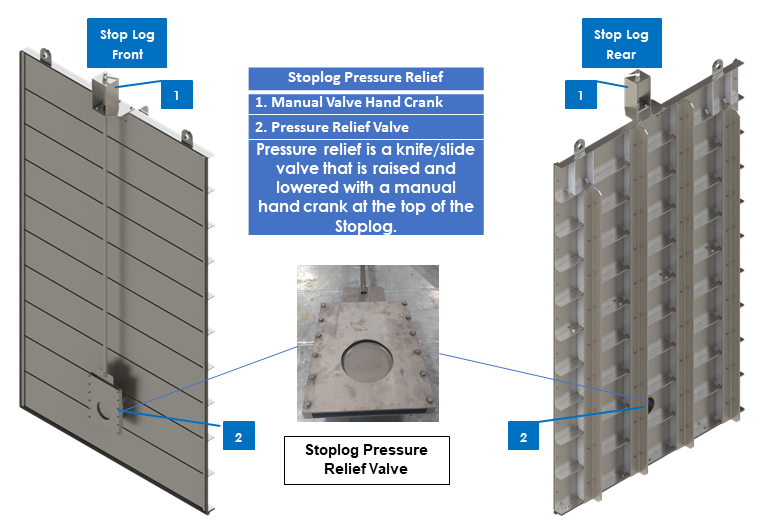

These metal logs are useful to reduce water flow or isolate an area for routine maintenance work. However, they can also be applied for field floods and water depth control over extended periods. They are handy in structures that require less maintenance and replacement. The stoplog design works as one unit to isolate a pump and will typically have a manually operated pressure relief valve at the bottom to equalize the water pressure for removal.

They are also essential for safety purposes. They can be used to prevent water flow in an emergency or to control water levels during flooding. Additionally, they prevent debris and other materials from entering the water screen system, which can cause damage to the equipment and reduce the system’s efficiency.

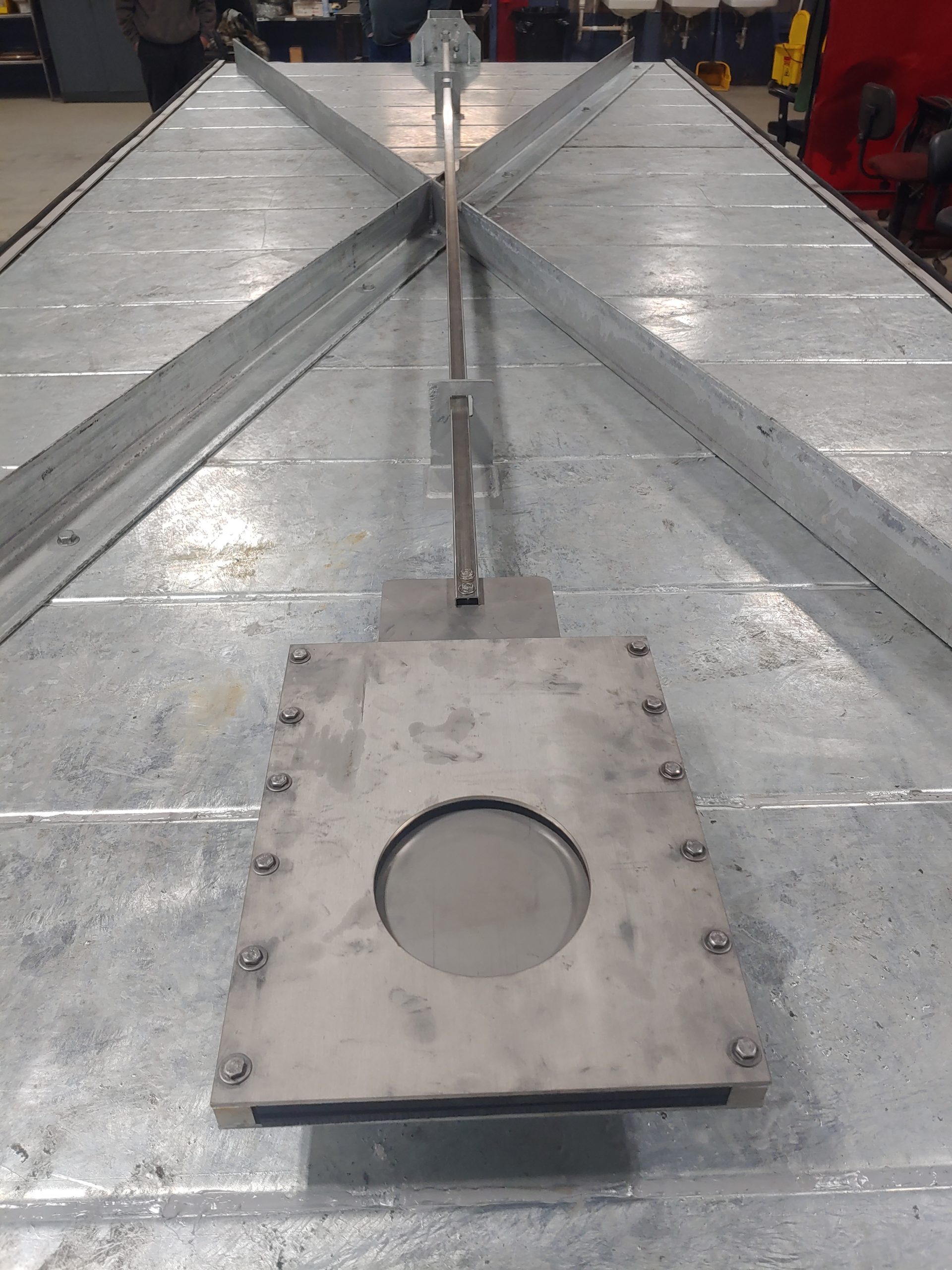

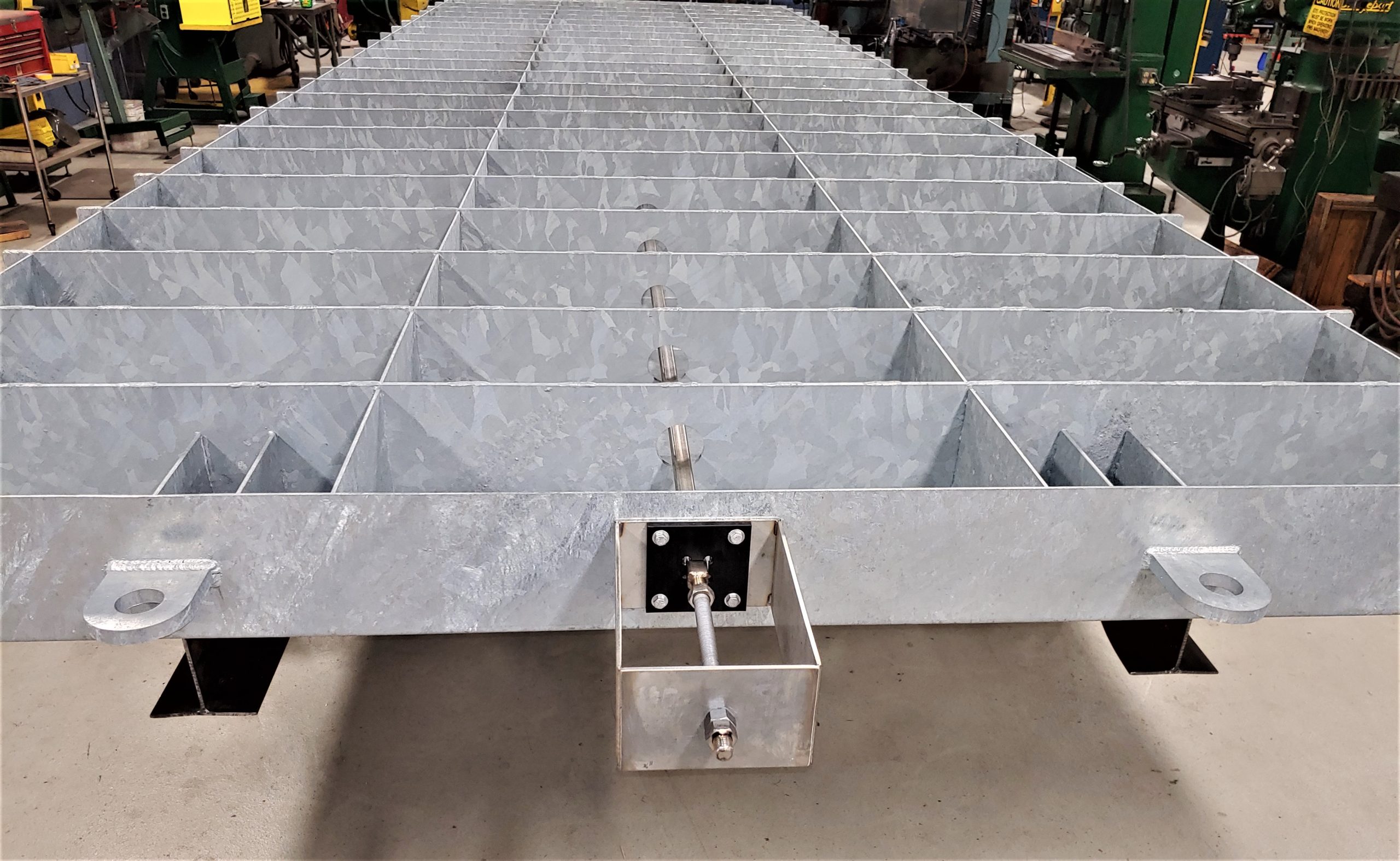

Pictures of the Stoplog (6’9” wide x 16′ 3” tall) showing the engineered lifting lugs, vertical & horizontal structure, the manual handle to operate the pressure release valve and the pressure release valve on the 2nd photo.

Water stoplogs can be applied to:

- Cooling towers and pumps

- Flood control

- Dams

- Irrigation systems

- Power stations

- Canals

- Hydroelectric plants

Stoplog Advantages

Helpful in a multitude of industries and have considerable advantages over other types of water flow control systems, these components are advantageous because of their following characteristics:

- Easy installation

- Lightweight

- Cost-effective

- Non-corrosive

- Come in varying sizes

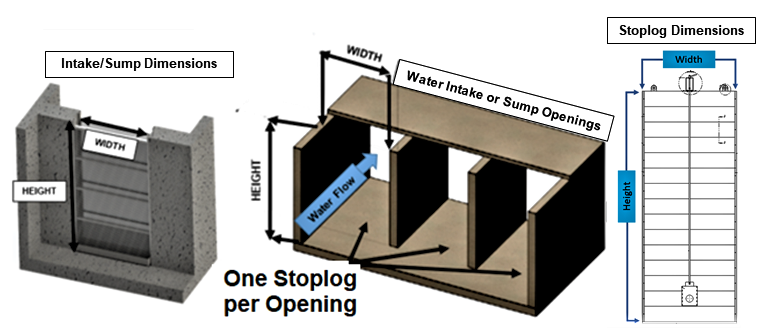

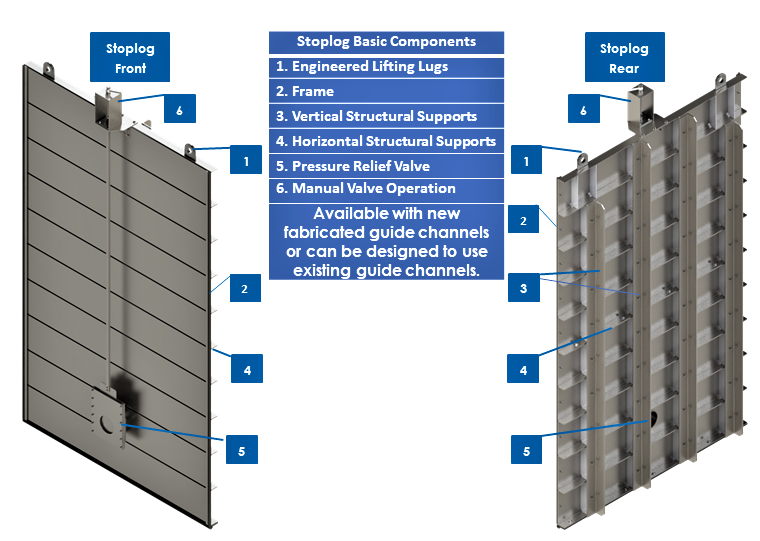

Example of front & rear view of a Stoplog (16’ tall x 6.5’ tall) in one complete unit without a pressure relief valve. The Stoplog is 1 of 2 that were designed to slow the volume of cooling water flowing into a water intake off a river as part of a EPA 316b regulation compliance project.

Our stop log gate and water screen systems are the superior choice. Here’s why:

Made of high-quality materials that are designed to last.

They are resistant to corrosion, abrasion, and other forms of damage, making them ideal for harsh environments.

Customizable to suit the specific needs of the application.

Depending on our customer’s requirements, they can be made in various sizes, shapes, and materials.

Designed to be highly efficient.

Our systems improve the performance of the water screens, reducing operating costs and increasing productivity.

Why Choose Us?

Cambridge Water Screen Systems is the undisputed nationwide water screening and filtering leader.

Our business has been prominent in agriculture and water control for over a century. We are a Regal Rexnord company, the largest manufacturer of metal conveying and engineered woven mesh solutions. By choosing us, you are choosing quality and professionalism.

We are committed to providing our customers with the highest quality products and services in the market. We use only the best materials and manufacturing processes to ensure that our screening systems are of the highest quality. We also provide excellent customer service and support, helping customers keep their water screen systems operating smoothly.

Ready to get started?

Are you looking for reliable water screen manufacturers? Contact Cambridge Water Screen Systems today and ask one of our professionals for an estimate. Our company will ensure the highest quality components for your future projects. Call (443) 331-5520 today or complete our contact form. We look forward to hearing from you.